PPG Working with Industry Partners to Develop Innovative Eco-Friendly Ship Hull Film System

PPG’s protective and marine business has received EU Funding for a new project which aims to produce an innovative fouling protection system for commercial vessels.

A project development group including PPG, MACtac, Meyer Werft/ND Coatings, VertiDrive and Hamburg Ship Model Basin HSVA are currently working together to establish an automatic application process for allowing an innovative self-adhesive/fouling release film to be used on commercial sea-going vessels. This process will allow shipowners and operators to enjoy the superior fouling release properties and drag reduction capabilities of the PPG SIGMAGLIDE self-adhesive film.

PPG Product Manager Christophe Cheikh says, “The eSHaRk (eco-friendly Ship Hull film system with fouling Release and fuel saving properties) project aims to bring to the market a fouling protection technology which not only maintains the current state-of-the-art fouling protection standards but is superior to existing paint-based solutions in terms of eco friendliness, easiness of application, robustness and drag reduction effects, all of which will lead to fuel savings and the reduction of GHG emissions.”

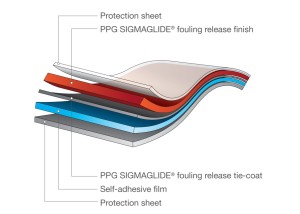

The system incorporates a fine-tuned fouling release system, based on PPG’s premium 100% silicone binder technology, and a self-adhesive film specially designed by MACtac for underwater use.

As part of the eSHaRk project robotised application technology is being developed by VertiDrive which will be used to apply the film on large commercial vessels in an automated way. Furthermore, the surface morphology of the film will be optimised to enhance drag reduction, fuel savings and emissions reduction benefits to a level previously unattainable.

After extensive laboratory testing, including flow channel drag reduction experiments conducted in a state of the art flow channel at HSVA, several small scale in practice applications have been successfully conducted and PPG is now looking for full scale testing and validation in operational conditions before market entry with the support of ND Coatings/Meyer Werft.

The number of trial applications is continuously growing and the advantages of the system are being clearly demonstrated. To date, the film system is offering clear advantages at newbuild stage.

Going forward, both the number of trials, as well as the size of trial vessels will be increased in order to validate the system thoroughly prior to full scale commercial launch. This validation phase will confirm the benefits for the ship operator in terms of fuel consumption and greenhouse gas emission reduction.