Robotised Flange Welding System For IHC Piping

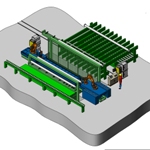

Kranendonk Production Systems B.V. has received a major order for a flange welding system from IHC Piping B.V. The system has been developed to incorporate four ABB simultaneously operating robots and the latest vision technology to position, tack and weld a wide range of flanges and welding sockets. Optionally the system can be equipped with cutting and drilling functionalities.

Kranendonk Production Systems B.V. has received a major order for a flange welding system from IHC Piping B.V. The system has been developed to incorporate four ABB simultaneously operating robots and the latest vision technology to position, tack and weld a wide range of flanges and welding sockets. Optionally the system can be equipped with cutting and drilling functionalities.

By integrating offline programming software with the current CAD/CAM system drastic cost savings will be realised at the work preparation department. Twenty-five years ago, IHC Piping B.V. was inspired by the principles of Lean Manufacturing (LM) and Just-In-Time (JIT) processes. These tried-and-tested Japanese production philosophies are utilised by IHC Piping to help boost efficiency and reduce wastage.

Arie Kranendonk (left) and IHC Piping Director Paul Dits (right) signed the contract for the flange welding system. “We will take delivery of the first robotic flange welding system in the Benelux countries and Germany”, said Paul Dits, Director of IHC Piping B.V. “It will help to improve the weld quality, the flexibility of production, and the cycle and delivery times for the pipe sections. These benefits will be passed on directly to our expanding customer base and provide us with a distinct competitive advantage.”

Arie Kranendonk (left) and IHC Piping Director Paul Dits (right) signed the contract for the flange welding system. “We will take delivery of the first robotic flange welding system in the Benelux countries and Germany”, said Paul Dits, Director of IHC Piping B.V. “It will help to improve the weld quality, the flexibility of production, and the cycle and delivery times for the pipe sections. These benefits will be passed on directly to our expanding customer base and provide us with a distinct competitive advantage.”