Nitrogen Membrane Technology For Prelude Project

Shell has appointed Air Products to deliver nitrogen membrane technology for Shell’s Prelude FLNG project to be launched outside Australia. Air Products also states that the majority of all new LNG ships on order, will be fitted with their technology. “Currently, we feel an increasing focus on gas and we are proud to be one of the preferred suppliers in this area, both for shipping companies as well as for the processing industry”, says Tom Cantero, Air Products.

Shell has appointed Air Products to deliver nitrogen membrane technology for Shell’s Prelude FLNG project to be launched outside Australia. Air Products also states that the majority of all new LNG ships on order, will be fitted with their technology. “Currently, we feel an increasing focus on gas and we are proud to be one of the preferred suppliers in this area, both for shipping companies as well as for the processing industry”, says Tom Cantero, Air Products.

The sceptical view on nuclear power that has followed the tragic earthquake in Japan earlier this year is one of the reasons for an increasing interest in gas. More than sixty gas tankers are currently on order, leading to the need of large-scale production plants. Shell is taking a lead and shows an innovative and future oriented approach, which has lead to the decision to move storage and processing facilities close to the fields rather than transporting unprocessed gas over large distances.

Intense

“The order to the Shell Prelude project results from several years of intense development. Air Products invented the technology behind membrane-based nitrogen production and we have expressed a clear ambition to continue leading the market. We are very proud to deliver to the world’s first floating LNG facility and see this as an appreciation of our work, quality and products”, the Air Products’ managing director continues.

Membrane-Based Production

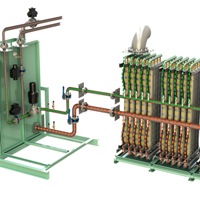

Air Products was first to launch compact systems for membrane-based production of nitrogen on ships and offshore installations. Originally, this was used to prevent explosions on board vessels by using nitrogen during loading and unloading LNG, but the systems have proven to be very successful in other areas as well, such as treatment of ballast water, conservation of food during transportation as well as prolonging vessels’ tank systems.

Air Products was first to launch compact systems for membrane-based production of nitrogen on ships and offshore installations. Originally, this was used to prevent explosions on board vessels by using nitrogen during loading and unloading LNG, but the systems have proven to be very successful in other areas as well, such as treatment of ballast water, conservation of food during transportation as well as prolonging vessels’ tank systems.

“We look positively on the increasing gas market. We can already see gas becoming the most important alternative to nuclear power, especially in Japan and Germany, as well as being used as fuel for cars and ships. We are committed to do our best in order to give the technology a leap forward”, Tom Cantero finalises.

Huge Production Facility

The new huge production facility is to be built into an FLNG vessel, measuring 488 m in length and 74 m in width, displacing some 600,000 t when fully loaded, of which 260,000 t are steel. Gas production is to commence in 2017 and the vessel is expected to stay moored at location for 25 years. The production is estimated to be at least 3.6 million t of LNG per years as well as Liquid Petroleum Gas and condensate for export.

The new huge production facility is to be built into an FLNG vessel, measuring 488 m in length and 74 m in width, displacing some 600,000 t when fully loaded, of which 260,000 t are steel. Gas production is to commence in 2017 and the vessel is expected to stay moored at location for 25 years. The production is estimated to be at least 3.6 million t of LNG per years as well as Liquid Petroleum Gas and condensate for export.