Kongsberg, DNV & IBM Consortium To Develop Integrated Environmental Monitoring System

A consortium consisting of Kongsberg, IBM, and DNV will develop a real-time environmental monitoring solution together with their client Statoil. On behalf of the consortium, Kongsberg has been awarded a contract by Statoil Research and Development Center in Trondheim for developing an Integrated Environmental Monitoring System. The project value of NOK 150 million includes Statoil’s project work and cash contribution and the consortium’s contribution.

A consortium consisting of Kongsberg, IBM, and DNV will develop a real-time environmental monitoring solution together with their client Statoil. On behalf of the consortium, Kongsberg has been awarded a contract by Statoil Research and Development Center in Trondheim for developing an Integrated Environmental Monitoring System. The project value of NOK 150 million includes Statoil’s project work and cash contribution and the consortium’s contribution.

Statoil is contributing NOK 75 million, while the remaining NOK 75 million is being split among the consortium members. The technology will be tested out at Kongsberg Maritime Subsea on the seabed of the harbour basin in Horten. The contract period is 3 years ending with a solution ready for pilot implementation at an operational asset. The project is part of Statoil’s ‘New Energy and HSE’ R&D programme and led by Kongsberg, using integrated technology to create a step change for the operators’ access and operational usage of environmental data.

Continuous environmental monitoring

The consortium is led by Kongsberg Oil & Gas Technologies, and includes Kongsberg Maritime Subsea providing sensor and communication technologies, IBM providing information integration and business analytics technology, and DNV providing marine environmental analytics and risk management practices. Statoil will have an active role in the project contributing with domain knowledge within offshore oil and gas operations.

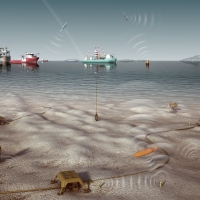

The purpose of the project is to demonstrate solutions for continuous environmental monitoring of operations in sensitive areas covering all phases of an offshore operation, i.e. from preparation, drilling, production and demobilization. A major benefit will be to include the environmental monitoring into the daily operation for early detection and reaction to potential environmental impact.

Unparalleled

“Kongsberg considers this project as an important step in its long-term strategy in developing integrated, continuous environmental monitoring systems to meet a growing demand for early detection and quicker response related environmental impact from offshore oil and gas activities”, says Even Aas, executive vice president Kongsberg – pictured here on the far right on board the Simrad Echo, together with (from the left) Karl Johnny Hersvik (Statoil), Jens Erik Ramstad (DNV), Morten Thorkildsen (IBM) and Vidar Hepsø (Statoil) (Photo: Ole Jørgen Bratland/Statoil).

“Kongsberg considers this project as an important step in its long-term strategy in developing integrated, continuous environmental monitoring systems to meet a growing demand for early detection and quicker response related environmental impact from offshore oil and gas activities”, says Even Aas, executive vice president Kongsberg – pictured here on the far right on board the Simrad Echo, together with (from the left) Karl Johnny Hersvik (Statoil), Jens Erik Ramstad (DNV), Morten Thorkildsen (IBM) and Vidar Hepsø (Statoil) (Photo: Ole Jørgen Bratland/Statoil).

“Based on our global leadership in environmental risk management and offshore HSE, DNV’s motivation is to set the standard for environmental monitoring. The development of efficient solutions for early warning monitoring and analysis of operations in sensitive areas will be of an unparalleled value to the industry. A major benefit will also be the integration of environmental monitoring into the daily operation”, says Jens Eirik Ramstad, associate director in Det Norske Veritas.

Unique Project

“IBM is proud to be part of this unique global project organised out of Norway, which also involves our R&D organisation, providing expertise and focus on Health, Safety and Environment. HSE is becoming increasingly important for the industries across the world. Environmental monitoring, as part of real-time integrated operations, is allowing IBM to drive further focus on HSE, not only as part of our world-wide Smarter Oil and Gas initiative, but also across several Natural Resource domains and industries”, says Morten Thorkildsen, general manager for IBM Norway.

Essential For Statoil

Statoil currently employs several environmental monitoring (EM) methods at its installations, mainly on the Norwegian continental shelf. However, there are no solutions available on the market that are integrated and enable physical, biological and chemical data to be measured during actual operations. “Environmental monitoring is essential for Statoil in order to achieve its target of zero harmful discharges. We are now signing a deal for a three-year research project and a lot of hard work remains to be done before we will know whether EM works as we hope it will. But if we succeed in taking environmental monitoring from being a separate task to become an integrated part of daily production, we will achieve even safer operations and reduced costs. This will represent a quantum leap for offshore environmental monitoring”, says Statoil R&D head Karl Johnny Hersvik.

Ever-Increasing Share

“An ever-increasing share of our production takes place subsea, in areas located far away from other infrastructure – such as the far north. The potential for EM as part of our day-to-day operations is considerable. EM will also make it possible to shut down production or cease construction activity during environmentally sensitive periods”, says Hersvik. EM works by attaching a number of sensors around an installation to measure live physical, biological and chemical data, making it easier to detect deviations. Considerable IT capacity is required to interpret the complete information flow from the sensors simultaneously, while coordinating monitoring with day-to-day operations.

Pre-Project Morvin Field

The correct application of information technology is therefore a pre-requisite for realising EM, and has accordingly been given a major role in this project. A pre-project was conducted in 2009 to investigate the effects of cuttings during the drilling on the subsea Morvin field in the Norwegian Sea, where substantial collections of corals have been found.

“The tests revealed no damage to the corals while drilling took place and extensive pictorial material provides no indication that adjacent corals were negatively impacted by the discharge of cuttings. This trial gave us some very valuable information about how to handle top-hole cuttings in environmentally sensitive areas. It is this kind of environmental monitoring we wish to integrate into our operations”, says Statoil EM project head Mona Låte.