Flexlife Completes First Application Of FlexGel

Flexlife has announced the successful first application of its innovative product FlexGel in a North Sea operation following consultation with the HSE (Health & Safety Executive) by Flexlife for an oil major. FlexGel was devised to halt corrosion of damaged areas of flexible risers or umbilicals within caissons and help safely extend the operating life of assets within the oil and gas production process. FlexGel is non-soluble in water. Its density can be adjusted depending on the application.

Flexlife has announced the successful first application of its innovative product FlexGel in a North Sea operation following consultation with the HSE (Health & Safety Executive) by Flexlife for an oil major. FlexGel was devised to halt corrosion of damaged areas of flexible risers or umbilicals within caissons and help safely extend the operating life of assets within the oil and gas production process. FlexGel is non-soluble in water. Its density can be adjusted depending on the application.

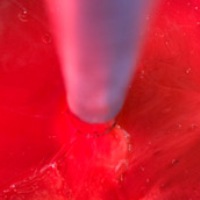

The patented oil-based substance can be pumped into a caisson to completely surround a riser with an annulus breach, displacing seawater and preventing further corrosion in the structural tensile armour wires of the flexible pipe, increasing the possible lifespan of the riser.

Annulus Breach

In this particular North Sea project an annulus breach was discovered during testing by Flexlife in a 4.5inch gas main flexible riser at a point 4.5 m subsea. 9,500 l of FlexGel was deployed to fill the I-tube from 11.5 m above seawater levels to 33.5 m subsea. FlexGel was pumped in approximate metre increments above the MSL 9 (Mean Sea Level) within the I-tube. This deployment method allowed time for the FlexGel to settle and displace all water and air to fully surround the breach.

Common Problem

Flexlife director of strategic development, Stuart Mitchell, says: “It is common for the outer sheath of flexible risers and umbilicals to be damaged either during installation or even by regular friction caused during operation. If the problem is left unaddressed, it can lead to rapid corrosion of tensile armour layers and premature pipe failure.”

Advantage

“The enclosed area inside a caisson is particularly problematic because there is restricted access for inspection and damage usually occurs around the splash zone level where oxygenated seawater can cause accelerated corrosion. The advantage of FlexGel is that it can be deployed from topside or subsea without the need for costly intervention by rope access or diving teams and the associated health & safety risks of those types of operation”, Mitchell continues. “Once it’s in place, Flexlife carries out predictive engineering and testing of the flexible, setting a benchmark for continued operation and allowing the pipe to remain in safe service rather than having to be changed out at considerable expense.”

Highly Efficient Solution

He adds: “FlexGel provides a highly efficient solution for operators and major sub-contractors faced with costly change outs of risers. Our products are devised not only to resolve issues but also to prevent them from happening in the first place. We believe there is a huge potential market for FlexGel as it is ideally suited for the large number of flexible pipe driven fields off Brazil, Asia Pacific, West Africa as well as the North Sea.”