Ball and Taper Grip for Gentler Drill Pipe Handling

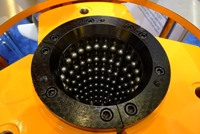

Blohm & Voss Oil Tools says its new SureGrip 500 floor slip is the first of a new generation of floor slip power tools using ball and taper gripping technology to provide improved drill pipe handling offshore. Conventional die slips fitted with replaceable steel die teeth create sharp indents in the pipe that can damage the pipe over time. Designed for loads up to 500 t, the SureGrip 500 ball-and-pocket gripping technology uses spherical balls in tapered pockets to replace die slip teeth, creating shallow, tear-drop shaped indents that minimise damage to the drill pipe.

Blohm & Voss Oil Tools says its new SureGrip 500 floor slip is the first of a new generation of floor slip power tools using ball and taper gripping technology to provide improved drill pipe handling offshore. Conventional die slips fitted with replaceable steel die teeth create sharp indents in the pipe that can damage the pipe over time. Designed for loads up to 500 t, the SureGrip 500 ball-and-pocket gripping technology uses spherical balls in tapered pockets to replace die slip teeth, creating shallow, tear-drop shaped indents that minimise damage to the drill pipe.

The SureGrip 500 floor slip provides a 360o multi-point grip in proportion to the load applied, resulting in evenly distributed loads from top to bottom, even on out-of-round pipe. In addition, the floor slip creates evenly distributed hoops stresses unlike conventional die slips, maintaining the integrity of the casing under high loads.

“The SureGrip 500 marks a step change in floor slip pipe handling. It significantly reduces the damage to pipe, compared with die slips, during handling operations. Moreover, it holds out the prospect of longer lasting floor slip tools that will increase the efficiency of drilling operations,” says Jens Lutzhöft, Division Manager, Oil Tool Division.

The SureGrip 500 floor slip is based on ball and taper technology developed by First Subsea Ltd for Canrig Drilling Technology’s SureGrip range of automated casing running tools.

For more information on the Blohm & Voss SureGrip 500 floor slip contact Matthias Theiss, CEO/President (USA), Blohm+Voss Oil Tools LLC, on matthias.theiss@blohmvoss.com.

For more information on First Subsea’s ball and taper technology contact Brian Green, general manager, First Subsea Ltd on briang@firstsubsea.com and visit www.firstsubsea.com.

– ends –

Caption: Blohm & Voss Oil Tools SureGrip 500 floor slip showing ball and taper pipe grippers.