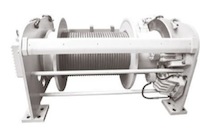

New Compact Electric Winch

The newly developed electric drive rope winch by Zollern has seen its first use, on Russian rigs. As part of a highly sophisticated mobile drilling system to depths of 5,000 m, Zollern uses an asynchronous motor designed in-house to meet the performance requirements of the rope winch.

The newly developed electric drive rope winch by Zollern has seen its first use, on Russian rigs. As part of a highly sophisticated mobile drilling system to depths of 5,000 m, Zollern uses an asynchronous motor designed in-house to meet the performance requirements of the rope winch.

By including their own drive unit and gearbox, Germany-based Zollern provides all the core components for the new compact electric winch. The company can thereby customise solutions for special customer applications.

The 340 kW, oil-cooled motor has been developed and produced in-house, as has the two-stage planetary gear. Both components have been adjusted seamlessly one to the other and optimised for this application. They ultimately exert a cable pull on the drum of 160 kN and a maximum speed of 600 m/min. An additional hydraulic emergency drive with two spur wheel gear stages will ensure that, if the main drive unit were to fail, the drill system can be drawn out of the drill hole to prevent damage.

Peter Berger, designer of the new rope winch, stresses that “This first application of our new series of electric winches de- manded everything from us. Because it is mounted on the vehicle, it was impossible for the winch to be even 10 mm wider, so we had to optimise every single detail. We had to carry out this space-saving optimisation keeping the demand for protection from explosion accidents in mind.”

The requirement for protection from explosion accidents, for which the final approval is issued by the TÜV [Technischer Überwachungsverein, German Technical Inspection Authority], is due to the high risk of explosion in gas drilling. To implement this demand, all heat-producing components had to be in an enclosed capsule design. Even braking temperatures could not exceed 200 °C.

Ulrich Niele, managing director of the project developer delta P GmbH, gives the following reasons for this first use of an electrically driven rope winch: “In this performance class and under these operating conditions, we would most probably have had problems with control of the hydraulics. Also, we have repeatedly observed that in Russia the attention paid to hydraulic systems during maintenance is not particularly outstanding, which can lead to more frequent malfunctions. We therefore find the new Zollern system very convenient.”

More on winches

Image courtesy of Zollern