Pipeline Pressure Isolation by TDW

T.D. Williamson (TDW) has successfully completed a pipeline pressure isolation operation in the southern part of the Norwegian North Sea on behalf of a major operator.

T.D. Williamson (TDW) has successfully completed a pipeline pressure isolation operation in the southern part of the Norwegian North Sea on behalf of a major operator.

TDW was called in to help prepare for maintenance works on an Emergency Shutdown Valve (ESDV) on a 20-inch main gas export line. To achieve this, TDW was contracted to isolate the affected portion of the line and perform a pressure test after completion of the ESDV repairs. TDW provided a wide range of services, including gauge and batch pigging, pipeline isolation and pressure testing.

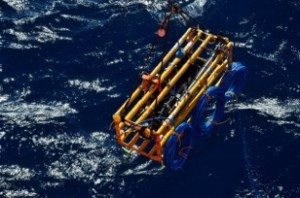

TDW needed to verify the piggability of the line to ensure that its remote-controlled SmartPlug pipeline isolation tool would be capable of negotiating the pipeline to the set location and be easily retrieved to the launcher. For this purpose, a full-scale piggability test was carried out at TDW’s onshore test facilities prior to the offshore operation.

Remote-controlled technologies keep operation on track

Working from a platform, TDW performed a gauge pig run on the affected line to further assess the likely success of the operation. Once this was completed, preparations were made to isolate the line by pigging a batch pig 40 yards (37m) from the platform. This was followed by launching a triple-module SmartPlug tool, which was pigged through the ESDV until it reached its set location, just before reaching a bend in the riser. TDW technicians used the remotely-operated SmartTrack tracking and monitoring system to continuously monitor the SmartPlug tool as it traveled to its set destination. The SmartTrack system uses two-way, through-wall, electromagnetic communication between an external transponder and the receiver in the tool to track its progress. Once the SmartPlug tool was set, the pipeline was isolated and sealed against a pressure of 60 bar (870 psi) for 10 days.

Working from a platform, TDW performed a gauge pig run on the affected line to further assess the likely success of the operation. Once this was completed, preparations were made to isolate the line by pigging a batch pig 40 yards (37m) from the platform. This was followed by launching a triple-module SmartPlug tool, which was pigged through the ESDV until it reached its set location, just before reaching a bend in the riser. TDW technicians used the remotely-operated SmartTrack tracking and monitoring system to continuously monitor the SmartPlug tool as it traveled to its set destination. The SmartTrack system uses two-way, through-wall, electromagnetic communication between an external transponder and the receiver in the tool to track its progress. Once the SmartPlug tool was set, the pipeline was isolated and sealed against a pressure of 60 bar (870 psi) for 10 days.

During the isolation period, maintenance works on the ESDV were safely carried out. Upon completion, TDW verified the integrity of the repaired valve by using the third module of the SmartPlug tool to perform a pressure test at 120 bar. Replacement of a double-block and bleed valve on the ESDV necessitated a second pressure test, which was readily executed by setting the third plug module of the SmartPlug tool for a second time. Satisfied with the results, the operator returned the line to full production, secure in the knowledge that the valve had been successfully repaired. The entire operation was carried out according to plan, well within the timeframe required.

“As with every operation we execute, we worked very hard with the customer to make absolutely  certainthat the operation went to plan,” said Bernt Andersen, Project Manager for TDW Offshore Services. “It’s heartening to know that as a result of our joint efforts and dedication to safe working practices that the line was efficiently repaired and tested, and that we contributed to that success,” he added.

certainthat the operation went to plan,” said Bernt Andersen, Project Manager for TDW Offshore Services. “It’s heartening to know that as a result of our joint efforts and dedication to safe working practices that the line was efficiently repaired and tested, and that we contributed to that success,” he added.