100 Years of Marine Distress Signals

Combining Fireworks, Aircraft Engineering and Line Throwers

Combining Fireworks, Aircraft Engineering and Line Throwers

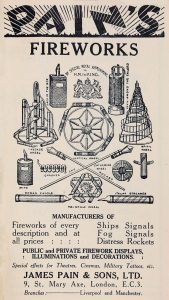

Pains Wessex has been a leading supplier of marine distress signals for well over 100 years. The brandevolved from three very different companies: fireworks business James Pain & Sons, the Wessex Aircraft Engineering Company (WAECO) and Schermuly, the manufacturer of the first rocket-powered line thrower.

The origins of the Pains Wessex name can be traced right back to 1620, when reference was made in the London Gazette to a “Gunpowder seller” by the name of Pain. Little is recorded of the company in the early days, but in 1850, James Pain & Sons was formed in Brixton. The first recorded move by the company into marine pyrotechnics was in 1873, when they took out a patent for a marine distress flare. James Pain and Sons continued to expand, manufacturing both fireworks and, increasingly, commercial pyrotechnics. In 1965, James Pain and Sons Ltd merged with the Wessex Aircraft Engineering Company Ltd to form Pains Wessex Limited.WAECO was set up at High Post, near Salisbury, Wiltshire, in 1933 to manufacture a range of pyrotechnic products for the War Office. They included wind direction smoke generators, chemical and lachrymatory naval smoke generators.

Go back to 1897 and the final third of the original Pains Wessex companies was making history. That year, Schermuly, a Surrey-based firm specialising in marine pyrotechnics and life-saving equipment, produced the first practical ship-to-shore rocket-powered line throwers, signal flares and allied search and rescue appliances. It specialised in manufacturing pyrotechnic devices used during World War II. In 1973, Pains Wessex Ltd acquired Schermuly, consolidating its position in the pyrotechnics market. Pains Wessex ceased fireworks production in 1976 when it was decided that this product no longer complemented its now specialised marine and military pyrotechnics activities. Schermuly’s Newdigate site was closed and production moved to Pains Wessex in 1980. In the early 2000s, Pains Wessex and Comet merged manufacturing, taking place in the Comet factory based in Bremerhaven, Germany.

Go back to 1897 and the final third of the original Pains Wessex companies was making history. That year, Schermuly, a Surrey-based firm specialising in marine pyrotechnics and life-saving equipment, produced the first practical ship-to-shore rocket-powered line throwers, signal flares and allied search and rescue appliances. It specialised in manufacturing pyrotechnic devices used during World War II. In 1973, Pains Wessex Ltd acquired Schermuly, consolidating its position in the pyrotechnics market. Pains Wessex ceased fireworks production in 1976 when it was decided that this product no longer complemented its now specialised marine and military pyrotechnics activities. Schermuly’s Newdigate site was closed and production moved to Pains Wessex in 1980. In the early 2000s, Pains Wessex and Comet merged manufacturing, taking place in the Comet factory based in Bremerhaven, Germany.

The Forefront of Marine Safety

In August 2012, leading marine solutions services specialist Drew Marine acquired Chemring Marine, which manufactured the Pains Wessex and Comet brands. Following this, in October last year, the Wilhelmsen Group signed an agreement to acquire the Technical Solutions business from Drew Marine, which did not include Drew Marine Signal and Safety, under which the Pains Wessex, Comet, Oroquieta and Aurora brands are manufactured and marketed. The new name, WesCom Signal and Rescue, came into effect on 16 October 2017. Under its new name, the company employs the latest technology, ensuring that the world’s leading marine distress signals are at the forefront of marine safety. Distributors and clients, including prominent search and rescue groups, such as teams from the Royal National Lifeboat Institution (RNLI), have toured the company’s Bremerhaven factory to see how products are manufactured.

WesCom Signal and Rescue has an ongoing programme of product research, development and innovation as well as distributor training. A strong focus on performance and safety considerations is a given, but the look and feel of products is regularly updated and improved. The company continuously seeks ways to reduce both product size andthe level of explosive content, while achieving the same or better results.

German Engineering

The EUR 2 million fully automated line at the WesCom Signal and Rescue manufacturing facility in Germany has the capacity to produce around 1.4 million red hand flares a year. By using the most sophisticated manufacturing techniques available, the highest levels of quality and safety are ensured. Automation allows for greater quality control and is much safer for staff. The explosive composition is automatically fed into the machine from an outside process shed, where it is pressed. It is a huge piece of equipment that takes up two large rooms. In between is a blast wall and a small aperture, that is always closed. This means that if anything goes wrong in the process shed, it doesn’t damage the production line.

“It really is an extraordinary piece of German engineering,” says Chris Feibusch, Global Head of Marketing and Communications at WesCom Signal and Rescue. “To provide some sort of comparison, I recently visited a pyrotechnic factory in China where the pyrotechnic compound was spooned into the flares by a team of operatives on a production line! Clearly, quality is almost impossible to control with this type of manual process.”

These are life-saving devices and cutting corners and regulations puts lives at risk. “Fake or cheap replicas of these products just can’t have this level of quality built in,” Mr Feibusch continues. “Tampered life-saving items being used without care or conscience for ship’s crew’s safety in distress or emergency situations could literally be a matter of life and death. It is imperative for buyers to remain vigilant – never accept safety-at-sea equipment if you have any doubts about its authenticity.”

Compact Lifebuoy Marker Makeover

Compact Lifebuoy Marker Makeover

The Compact Manoverboard Lifebuoy Marker (Mk 9) is the latest Pains Wessex product to feature a major upgrade, with a more compact LED and powered by lithium batteries. The MOB MK 9 used to be a much larger unit. Now, at 375mm, it can fit in a lifebuoy. The MOB MK9 produces dense orange smoke for 15 minutes and features two self-contained, inversion switched, LED lights which far exceed SOLAS requirements. Ships are required to carry 2 markers, one mounted on each bridge wing with the brackets supplied and attached by line to a 4kg lifebuoy. The signal is used to mark the position of a man overboard by day or night. It can be automatically deployed by releasing the attached lifebuoy, or manually activated. Safe to use on petrol or oil-covered water, the unit can be automatically or manually deployed from the stainless-steel mounting bracket. Including the bracket, the MOB lifebuoy marker weighs 3.8kg.

Some large tankers and oil rigs need to mount this marker at heights in excess of the SOLAS 30m requirement. To satisfy this need, the MOB MK 9 has been tested up to 60m, double the SOLAS regulations, which makes it suitable for use on oil and gas rigs. It conforms to all worldwide approval standards. The marker has individual LED light pods for quick installation and testing and a new retaining clip to prevent accidental deployment in rough seas. Its single-piece stainless steel bracket allows it to fit existing installations.

www.wescomsignal.com