Dynamic Yacht Platform heralds in a more efficient and customised design process

The ship design and engineering firm C-Job Naval Architects is moving the superyacht ‘fixed-hull platform’ concept a step further. With input from DNV GL, they are developing a dynamic platform for 50- to 80-metre yachts that works for various hull shapes, saving builders and owners construction time and cost.

The ship design and engineering firm C-Job Naval Architects is moving the superyacht ‘fixed-hull platform’ concept a step further. With input from DNV GL, they are developing a dynamic platform for 50- to 80-metre yachts that works for various hull shapes, saving builders and owners construction time and cost.

A significant challenge when building a new superyacht is to fullfill the owner’s wish for a custom boat without spending large amounts of time and money on designing and building a hull from scratch. Jeroen Jungschlager, Project Manager at C-Job, shares the company’s experience, “With our Northern European shipyard clients in the yacht building industry, we saw engineering design was taking quite a long time for each yacht. We had the idea that it could be improved and the process speeded up. Platforms are not new, but most are limited to a certain length and beam and have been developed by a yard’s in-house team. C-Job, as an independent company, came up with this new idea of a Dynamic Yacht Platform that could benefit several shipyards. We thought: How can we serve all these yards and make a platform which is not limited in size – one that can be stretched or shrunk within a range of 30m in length while offering a variable beam, as well?’”

Stefan van der Harst, a graduate naval architect from the University of Delft, picked up the baton for the Dynamic Yacht Platform within C-Job’s R&D department. “DNV GL expressed an interest in how it was going, and I followed up. We decided to involve DNV GL as they seemed enthusiastic.” Mr Jungschlager adds, “We investigated working together since DNV GL develops tools and systems and offers digitalised plan approvals. We started to explore the possibilities of developing the platform together, wondering how we might connect our tools.” C-Job invests extensively in research and development. Mr Van der Harst elaborates, “We have a large R&D division and encourage everybody in the company to contribute through an internal website by posting ideas that might get approved by one of the principal R&D engineers. If your idea is considered valuable, you can allocate time to work it up further as a naval architect, and other resources will be provided for it, supervised by the relevant office’s R&D head. For the Dynamic Yacht Platform, one person is presently working full-time on the project, and other members of the team are dedicating a number of hours to it every week.”

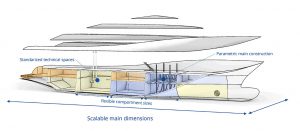

Jungschlager explains how the platform was developed: “The size range of the Dynamic Yacht Platform (from 50 to 80m of LOA) was decided on after we had done some market research and contacted a number of leading superyacht brokers, shipyards and designers. We noted that yachts above 100m really are a niche market. 50 to 80m seemed the biggest market for a platform.” Mr Van der Harst points to the flexibility of the platform regarding hull forms: “If a yard has its own signature hull shape, then we aim to fit the platform into that. The platform is more focused on the technical parts, while the exterior shape is subject to customization, so we want to keep that aspect as free as possible.” Mr Jungschlager sums up: “It is a yacht without a shape! It comprises the structural and mechanical components, everything inside, but without a pre-defined shape!” There are other platforms on the market but they tend to be more fixed or designated for a specific shipyard with limited scalability. C-Job’s platform is designed to be used by any yard, and the same platform can be adapted for completely different vessels. The most challenging task, according to Mr Jungschlager, was to identify those parts that can be scaled and their knock-on effects, such as considerable extra piping for a modest increase in length overall. “The platform is more focused on the technical parts, while the exterior shape is subject to customisation, so we want to keep that aspect as free as possible.”

The focus of the collaboration with DNV GL was to develop guidelines for both sides to work with, and establish an iterative process for elements such as watertight compartments and fire boundaries. “Ultimately,” Mr Van der Harst claims, “the Dynamic Yacht Platform could save some 4.5 months in build time and reduce the costs accordingly.” An especially interesting area where the development is progressing rapidly is the optimisation of the interior volume, especially the headroom, by reducing ventilation ducting in proportion to the scalable main frame. When asked about tender garages and hull openings, C-Job points out that items such as tender bays are treated as ‘functionality within the platform’ and remain entirely customizable by owners’ designers in terms of layout and location. Using standardised technical spaces and adjustable compartment sizes, the new yacht platform is flexible enough to support a wide range of popular hull lengths and widths.

Holger Jefferies, Head of Department at DNV GL – Maritime, agrees that there is considerable potential for time saving from the class and design approval point of view, as well. He explains that the aim of the collaboration is to achieve ‘approval in principle’ for the mid-point design, taking it as far as reasonable so that any future drawings C-Job will submit for full class can be processed quickly, mainly by cross-checking the calculations. DNV GL and C-Job are discussing how design and calculation tools can work together to create a software service that ideally will reveal immediately whether a design is compliant while it is being adjusted. Mr Jefferies is pragmatic about it though, noting “it may not actually be necessary in the 50 to 80m range as, from experience, there will more likely be two or three size brackets for each 10m of LOA range, and you will not change shell plating thickness for every 0.1m increase in LOA. A mid-point design and an overall structural layout that is scalable are more practical for a yard.”